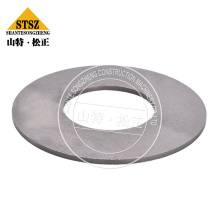

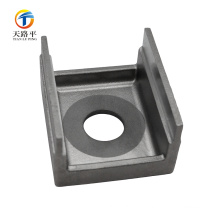

Sinter parts sintered powder metal filter

Product Description

Sinter parts sintered powder metal filter

1. main process: metal injection molding

2. Material: stainless steel, iron-copper etc.

3. MOQ:Small order can accept.

4. One-stop shopping for Customized Engineered products.

5. OEM/ODM service are welcome.

6. To chart to sample production.

Product specification

sintered powder metal filter | |

Equipment | cnc milling machine, CNC machining center etc; |

Drawing soft ware used | UG\PRO-E\SOLIDWORKERS2010\CAD etc; |

Inspection equipment | Three-coordinates measuring machine,Hardness-testing device,spectrum analyzer; |

Material | aluminum alloy, carbon steel, stainless steel,cast iron, pig iron,alloy steel,non-ferrous,grey iron,ductile cast iron ,Magnesium Alloy ,silicon steel, copper and so on. |

Machining precision | ±0.01mm; |

Weight range | 0.02-30kg |

Surface treatment | plating,anodizingpowder coating,spray-paint,electrophoresis; |

Delivery time | According to order quantity; |

Service | OEM/ODM service are welcome; Service |

Standard | DIN,AISI,ASTM,BS,JIS,etc. |

quality certification | ISO9001:2008 Approved |

Our main sinter parts category:

1.ABS Sensor Rings

2.Air Cylinder

3.Bevel GeaR

4.Bushing

5.Helix Gear

6.Lock Accessory

7.Oil Pump Rotors&Gears

8.Pulley

9.Rotors

10.Shock Absordber

11.Sprocket Wheel

12.Spur Gear

13.Valve Plate

14.Other Sintered PM Products

Material Available and Chemical Composition:

P/M Copper and Copper Alloys

P/M Iron and Carbon Steel

Iron And Carbon Steel

Iron-Copper And Copper Steel

Iron-Nickel And Nickel Steel

Low Alloy Steel

Commix Low Alloy Steel

Sinter Hardened Steel

Diffusion Alloyed Steel

Copper Infiltrated Iron And Steel

Sinter part/ Powder metal Sintered Parts are widely used for machinery, House hardware, Garden, Agricultural machines, Electrical power tools and etc.

The so called powder metals have 3 major advantages:

(A) High precision due to mold- Based production.

(B) Low price due to its inherent feature of automation for mass production.

(C) Flexibility of material composition due to wide variety of powder formula on Fe- Cu- Ni alloy. Besides, If the bearings and bushes are made of metallurgical metals, Then it becomes free of maintenance since the sintered metals have the inherent porosities for oil impregnation which has been well done as soon as the sintered bushes, Sintered gears or sintered parts are manufactured. In addition, The mechanical parts such as gears, Pivots and pinions can also be produced by metallurgy because the strength can be enhanced by heat treatment and adding nickel into the powder formula. Further more, More than 200 types of vehicle parts and motorcycle parts, I. E. , Metallurgical parts, Are made of sintered metals. This implies that the safety of long- Term operation for sintered parts (or powder parts) is pretty ensured. At last, In order to improve the ductility and elasticity of sintered metals (or sinter metal, Sinter parts, Sinter bush, Sinter gear) in machinery, The alloy that includes copper and iron becomes the main stream. This is only available by employing the technology of powder metallurgy and sintering.

A: Application Advantage of Powder Metallurgy Technology:

1). Powder Metallurgy Technology has the advantage of high precision, good performance and low cost while producing spare parts. Automobile manufacture industry is a bid application area of PM technology, involving the productivity, tolerance, automation and other aspects of spare parts.

2). Some products of certain unique properties and microstructure can only be achieved by PM Technology such as porous materials, dispersion strengthened alloys, ceramic and cemented carbine, etc. Besides, this kind of method is also adopted to manufacture high purity materials.

3). PM Technology can be used to manufacture materials that can hardly be made by other techniques, such as active metal, refractory metal, etc. The microstructure and structure of these materials can be inevitably and obviously damaged with the increasing temperature during the normal processing technology, while Powder Metallurgy Technology can avoid this kind of defect and just lays its advantage on this field.

B. Application of Powder Metallurgy Technology

1. Powder metallurgy material and its products have a large and extensive application.

2. From common machinery manufacturing to precision instrument, such as hard alloy,diamond-metal composite material, instrument parts, soft and hard magnetic material.

3. From hardware products to large-scale machinery, such as lock parts, typewriter parts, sowing machine parts, lathe machine parts and porous oil-impregnated bearings.

4. From electronics industry to motor manufacturing, such as electronic magnetic material, computer memory components, copper-graphite brush and vacuum electrode materials.

5.From mining to chemical industry, such as various kinds of ore machine parts, oil-impregnated bearings, chemical filter, antiseptic parts, catalyst.

6.From civilian industry to military industry, such as mechanical parts of automobiles, ships, tractors, etc., friction material, filters, and oil-impregnated bearings.

7.From general technology to most advanced science and technology, such as various medical equipments, completion penetrating warheads, bourrelets, ordnance parts, aerospace materials and components, etc., Atomic Industrial nuclear fuels, the reactor structural materials where all have the existence of PM Technology application.

All in all, powder metallurgy materials and products now play an essential role in electronics and automobile manufacturing, in general and advanced technology, in various sectors of civilian industry and aerospace fields.

C. Unique advantage of Powder Metallurgy Technology

1. can be made into the artificial alloy that doesn’t fuse with each other and whose proportion and melting point vary greatly in many cases;

2. contains uniform distribution of non-metallic components (such as graphite, silica, etc.) and the metal alloy;

3. can be made into certain products of unique properties or microstructure, such as porous materials, dispersion strengthened alloys, ceramic and cemented carbine, etc.

4. contains uniform grain structure of metals and alloys.

Product Categories : Machinery Parts

Premium Related Products